| CMC trough | X22B trough | |

| trough dimensions (mm) | -- width | 160 | 160 | -- length | 476 | 388 | -- depth | 12 | 6 |

| maximum area (cm2) | 762 | 620 |

| minimum area (cm2) | 80 | |

| constant pressure mode? | yes | yes |

| automated data collection? | yes | yes |

| automated trough control? | possible | possible |

| temperature control? | yes | yes |

| compression speeds (mm/min) | 0-180 | 0-180 | canister dimensions (mm) | -- width | ? | ? | -- length | ? | ? | -- depth | ? | ? | glass block dimensions (mm) | -- width | 152.5 | ? | -- length | 152.5 | ? | -- thickness | 12.0 | ? |

The CMC trough comes in two boxes, a large one containing the trough canister and

a smaller one containing the trough itself, the control unit, the connecting

cables and a box with various accessories. We have recently fitted the

trough canister with spacer plates to position the trough higher in the

canister and thereby decrease the time necessary to fill the trough with

helium. (Before you put the trough into the canister, it's a good idea to

clean it under the hood in the lab.) The levelling feet on the trough

fit into depressions in the top spacer plate. Make the connections between

the trough and the waterbath

hoses and the control box cable feedthroughs. In the cardboard accessory box,

find the surface pressure transducer, mount it on the post on the trough,

and connect the wires.

Hang the Wilhelmy plate and hook from the plastic loop on the transducer.

Mount the canister and the trough on the sample stage. The foot of the

canister near the window should be approximately centered on the center of

the sample theta, two-theta rotation stages. The other two feet, along with

a fair amount of the canister, will hang

over the side of the sample stage's adapter plate. Make the connections

between the canister feedthroughs and the circulating bath and the control

box cables. Level the trough using

the three adjustable feet on the trough. Put the (clean) glass block into

the trough and fill the trough with water.

At X22-B, you may have to mount the trough after an experiment not requiring the trough.

There is hardware at the beamline that holds the trough in place. (The plates are stored in the

X22 cabinet, along with the anti-vibration stages. The dogs for the anti-vibration stages are

in the cabinet in the hutch. The screws and bolts are in a green cardboard box in the hutch. The

anti-vibration controller and cables are beneath the table holding the 4-circle. ) See the photos below.

At the start of the run, it's best to clean the trough thoroughly under the hood. Put in gloves and wipe all the teflon surfaces of the trough with Kim-Wipes moistened with solvents (chloroform, methanol, acetone) and then wipe it dry. Collect the used wipes and gloves for appropriate disposal. Remember: chloroform is carcinogenic, so it is best to minimize its use and adhere to the Standard Operating Procedure for handling chloroform at CMC CAT.

We clean the glass block using nitric acid. Put on appropriate gloves and a lab coat. Remember: nitric acid and its fumes are corrosive. Under the hood, put the glass block into the tray and pour enough acid into the tray to cover the block, but try to minimize the volume used. Let the block soak while you clean the trough, mount it and calibrate it. Before you leave the block unattended, be sure to leave a note warning others that you have an open tray of nitric acid in the hood. Afterwards, pour the acid into a container appropriately labeled "used nitric acid," and save it for re-use and eventual disposal. Rinse the block with pure water several times. It should appear uniformly hydrophilic. If there are any hydrophobic patches, wiping them with kim-wipes wet with solvent in the manner described above for cleaning the trough should help. Soaking the block in a solution of detergent (Hellmanex or RBS) should also help, but be careful as this will require a lot of rinsing afterwards to ensure that all the detergent is washed from the block.

During a run operators need to find the right compromise that keeps the trough clean without taking too much time away from data collection. If consecutive monolayers are to be spread from the same or similar samples on the identical subphase, it is generally sufficient to aspirate the monolayer from the surface without exchanging the subphase completely. Since there is only a thin film of water between the glass block and the monolayer, be sure to add more subphase behind the moving barrier before you start aspirating. This will reduce the risk of the monolayer coming in contact with the block. Aspirate until the pressure is close to zero, move the barrier to the minimum position and aspirate again. Add some more subphase and aspirate again. With experience you will gain a feel for how much aspiration is sufficient to remove the monolayer completely.

Sometimes the trough needs to be cleaned more thoroughly, for example when

the next sample is very different, or requires a different subphase, or

if the previous monolayer's meniscus collapsed and contaminated the teflon

edges of the trough. Aspirate the monolayer carefully as just described,

then take out the block from the subphase and either put it aside (best to

keep it covered with clean water) or clean it. Then aspirate the subphase

completely and wipe down the trough and barrier as necessary, paying careful

attention to any hydrophilic patches you may have noticed. Be extra

careful using solvents in the hutch. Transfer a few milliliters to clean

vials for use in the hood. You don't need much to clean the trough. Collect

the contaminated Kim-Wipes and your gloves for disposal. Fill the trough

with clean water and aspirate it out a few times before returning the block

to the trough and adding the subphase for the experiment.

top

Vibration Isolation

top

Controling the Trough

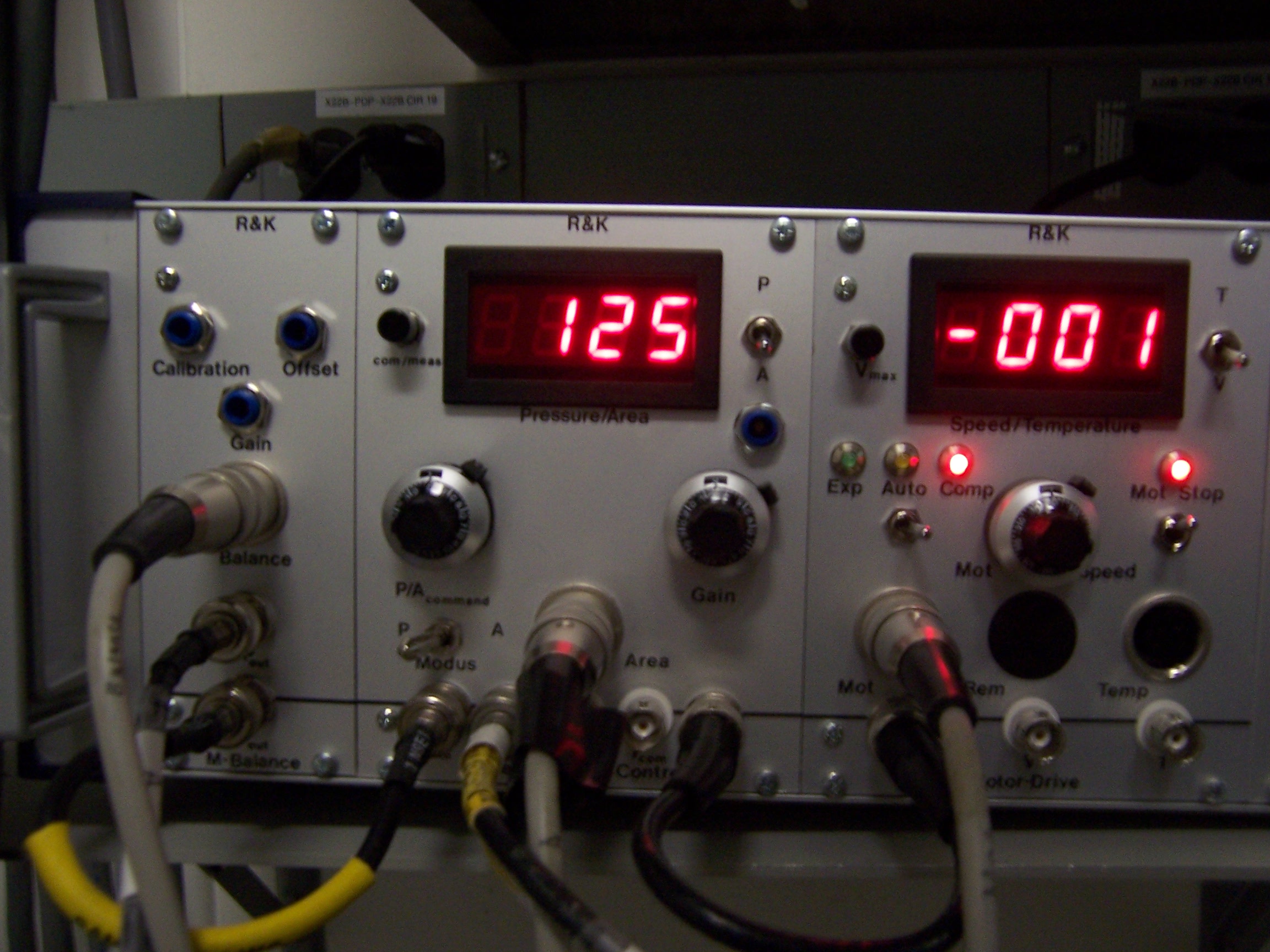

The trough control unit consists of three modules, as seen in the above picture. From left to right we see the Pressure, Area and Barrier modules. The Pressure module has three trimpots that affect the pressure calibration and offset, and the gain of the transducer. The area module has an LED display that displays pressure or area, depending on the setting of the togggle switch to the right of the display. Additionally, depressing the pushbutton to the left of the display switches the readout from 'MEASure' mode (current pressure/area displayed) to 'COMmand' mode (the pressure/area setpoint is displayed). The display on the barrier module shows a number proportional to the velocity of the moving barrier or the temperature of the probe in the subphase of the trough, depending on the setting of the toggle switch to the right. It contains the switches for moving the barrier manually or engaging constant pressure mode. The knob below the display determines the barrier speed.

Connect the trough control unit to power and connect all the cables from the

trough. Use short coax cables from the cardboard accessory box to connect

the Pout terminal from the Pressure module to the Pin

terminal on the Area module and the Sout terminal of the Area

module to the Sin terminal of the Barrier module. Now the

control unit can read out the total area of the monolayer, the surface

pressure and the temperature. To record pressure-area diagrams, interface

the control box with the computer running Surf. The details are different

for CMC CAT and X22B. At X22B, connect the Pout terminal to

the digital multimeter (labelled GPIB 03) located above the computer terminal

via the patch panel in the hutch. Similarly, connect the Aout

terminal to the DMM labelled GPIB 05. The macro below will tell Surf

how to read in the data. (Note that without a third DMM, there is no

provision for reading in the temperature from the probe in the subphase.

However, the NESLAB chiller can be computer-interfaced so that the bath

temperature can be recorded. See Elaine Dimasi's notes for the

chiller unit

on her

LSS documentation page.) At CMC CAT, the Pout, Aout

and T terminals should be connected to voltage to frequency converters

(VFC) in the B-Hutch and the output connected to scaler channels. See the

information in the macros section for more details.

top

Computer-Interfaced Control of the Trough

top

Trough Calibration

Pi calibration The filter paper used as the Wilhelmy plate should be 3 mm wide and should extend approx. 12 mm from the hole for the hook. For a coarse, but generally reliable, calibration:

Generally speaking, this calibration is sufficient. You may

want to test

things out by taking an isotherm of a standard substance, like arachidic acid.

top

Area calibration

It is possible to adjust the offsets of the electronics so that the area

signal is proportional to the total area of the trough, but the procedure

is cumbersome. It is more convenient to set the calibration in the software

instead. Both troughs are exactly 16 cm wide. Use a ruler and measure

the distance from the barrier to the front end of the trough for two different

points and record the voltage of the area signal at each position. The area

signal is very linear with barrier position, so from the two points you

can derive the slope and y-intercept of the line through the two area-voltage

pairs.

The constant pressure mode of the trough controller allows

you to compress the monolayer to a set pressure (or area) that you determine

and then maintain the monolayer at that pressure (or area). (The area

control is intended for different troughs with two moving barriers.) To

set the target pressure (0) check that the toggle switch at the bottom

of the middle module (modus) is in the P position; (1) look at the

LED display on the moddle module and make sure

that the toggle switch on the right side is set to pressure (P); (2) depress

the pushbutton (com/measure) to the left of the display; the LED display

now shows the target pressure; (3) turn the knob at the lower left of the

display (P/A command) until the desired target pressure is displayed.

To engage constant pressure mode (1) check that the toggle

switch on the right side of the right module (mot stop) is in the up position

and the LED is lit; (2) put the three-way toggle switch on the left side

of that module (exp auto comp) into the auto position; (3) as soon as you

toggle the (mot stop) switch to the down position, the monolayer will be

compressed until the target pressure is achieved. The Gain knob on the

middle module controls the characteristics of the feedback loop that moves

the barrier. To disengage constant pressure mode toggle the

mot stop switch to the up position and stop the barrier motion, or put the

three-way switch into the exp or comp position, which will immediately start

expanding or compressing the monolayer.

def iso '

def _cleanup3 \'

PL_G = 0

PL_X = 0

PL_Y = 1

rdef scan_plot "_plot"

\'

rdef scan_plot "isoplot ; _plot"

data_grp(ISO_GROUP, 4096, 5)

PL_G=ISO_GROUP

PL_X=2

PL_Y=4

ascan sh A[sh] A[sh] 4000 1

'

top

Isotherm Macros

global PRESSURE # last pressure reading

global PRESSURE_SLOPE # linear coefficient for pressure reading

global PRESSURE_OFFSET # constant term for pressure reading

global AREA # last area reading

global AREA_SLOPE # linear coefficient for area reading

global AREA_OFFSET # constant term for area reading

global DEGC # temperature

global ISO_GROUP # group number for isotherm data (choose 7)

PRESSURE_SLOPE = 10

PRESSURE_OFFSET = 0

#####March 2001 values for correctly calibrated trough (readout

#####on control unit is accurate

AREA_SLOPE = 109.7

AREA_OFFSET = -1.2464

ISO_GROUP = 7

def getpia '

PRESSURE=gpib_get(3)*PRESSURE_SLOPE+PRESSURE_OFFSET

AREA=gpib_get(5)*AREA_SLOPE+AREA_OFFSET

'

def press '

getpia

print "Pressure = ", PRESSURE, "\tArea =", AREA

'

#measure1 is called from the "scan_loop" in the standard macros

def measure1 '

getpia

'

def iso_Fheader '_cols += 3;printf("#X %gKohm (%gC)\n", TEMP_SP,DEGC_SP)'

def iso_Plabel 'sprintf("%7.7s %7.7s %8.8s ","Area","T-degC","Pressure")'

def iso_Pout 'sprintf("%7.5g %7.5g %8.5g ",AREA,DEGC,PRESSURE)'

def iso_Flabel '"Area DegC Pressure "'

def iso_Fout 'sprintf("%g %g %g ",AREA,DEGC,PRESSURE)'

def iso_Ftail ''

rdef Fheader "iso_Fheader"

rdef Plabel "iso_Plabel"

rdef Pout "iso_Pout"

rdef Flabel "iso_Flabel"

rdef Fout "iso_Fout"

rdef Ftail "iso_Ftail"

# this macro stuffs the scan data at each point of the scan

# 9/26/98 Put in commands to fix plotting ranges--seems to work.

def isoplot '

_sx = _sx * 1.16 - 0.4

_fx = _fx * 1.16 - 0.4

data_put(ISO_GROUP, NPTS, 2, AREA)

data_put(ISO_GROUP, NPTS, 3, DEGC)

data_put(ISO_GROUP, NPTS, 4, PRESSURE)

X_L = "Area"

Y_L = "Pressure"

'

top